2024 STUDENT CHALLENGE

(Click here to view the 10 year history of the various challenges):

Call for Participation: Ball Roundness Metrology.

The ASPE Student Challenge committee is excited to announce this year’s challenge: Ball roundness metrology using a precision air bearing. The Student Challenge will be held as part of the ASPE annual conference in Houston, Texas, November 4-8. Student teams from the United States and international universities will participate. A network of professionals from ASPE will support the teams both during preparation, and the competition. Precision air-bearing spindles play a crucial role in modern manufacturing and measuring technologies. Student teams will -employ the spindle to measure the roundness of a 25.4 mm diameter stainless steel ball using Donaldson ‘reversal’ technique. In spindle metrology, the technique to separate the form error of the calibration artifact from the spindle system errors was first demonstrated by ASPE 1995 Lifetime Achievement Award recipient Bob Donaldson. Using reversal, measurement errors can be reduced below the form error of the calibration artifact.

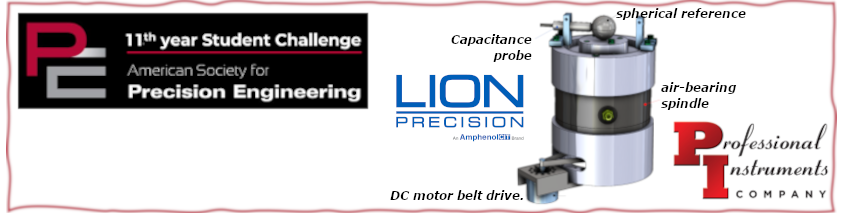

To measure the ball roundness, student teams will use; a Professional Instruments 3R Air Bearing Spindle with radial error of less than 25 nanometers, a Lion Precision sub-nm resolution capacitance probe with 50 µm range. The primary goal is to demonstrate how the reversal method decouples the measurement artifact errors from the spindle errors and evaluate the factors that prevent the uncertainty of these measurements from approaching the limits of the measuring probe.

While the challenge topic is to measure ball roundness, typically the ball is used to measure the radial, and tilt errors of the spindle motion. Spindle metrology is integral to ensuring the quality and performance of instruments and machines affecting various aspects of modern life and impacting industries such as transportation, energy generation, healthcare, security, electronics, nanomaterials fabrication, aerospace, optics manufacturing, metrology, and more. The Donaldson Reversal principle offers a reliable and efficient method for spindle metrology, providing engineers with valuable insights into spindle performance and aiding in the enhancement of manufacturing precision.

Figure 1. Setup used for our competition.

Important Link:

Calendar:

- October 2, 2024: Challenge begins.

- October 18, 2024: (11 am -12 pm EDT): Preliminary Presentation.

- November 4, 2024 (6:00 PM – 11:59 PM): Competition at the conference.

- November 6, 2024 (12:00 Noon – 1:30 PM): Presentations at the conference.

Registration and Sponsorship Links:

For questions or comments please email us at aspe.challengecommittee@gmail.com

Last Edited: October 22, 2024 LAA

Sponsors

Platinum Sponsor Student Challenge |

Platinum Sponsor Student Challenge |

Silver Sponsor Coffee Break |

Silver Sponsor Student Challenge |

Center for Precision Metrology Bronze Sponsor Student Challenge |

Platinum Sponsor Dinner at Space Center Houston |

Platinum Sponsor Student Challenge |

Platinum Sponsor Student Challenge |

Nanoscale Design and Manufacturing Laboratory UT-Austin Bronze Sponsor Student Challenge |

Platinum Sponsor Student Challenge |

Platinum Sponsor Student Challenge |

The William States Lee College of Engineering Platinum Sponsor Student Challenge |

The Wisconsin Electric Machines and Power Electronics Consortium Bronze Sponsor Student Challenge |

Platinum Sponsor Student Challenge |

Silver Sponsor Coffee Break |